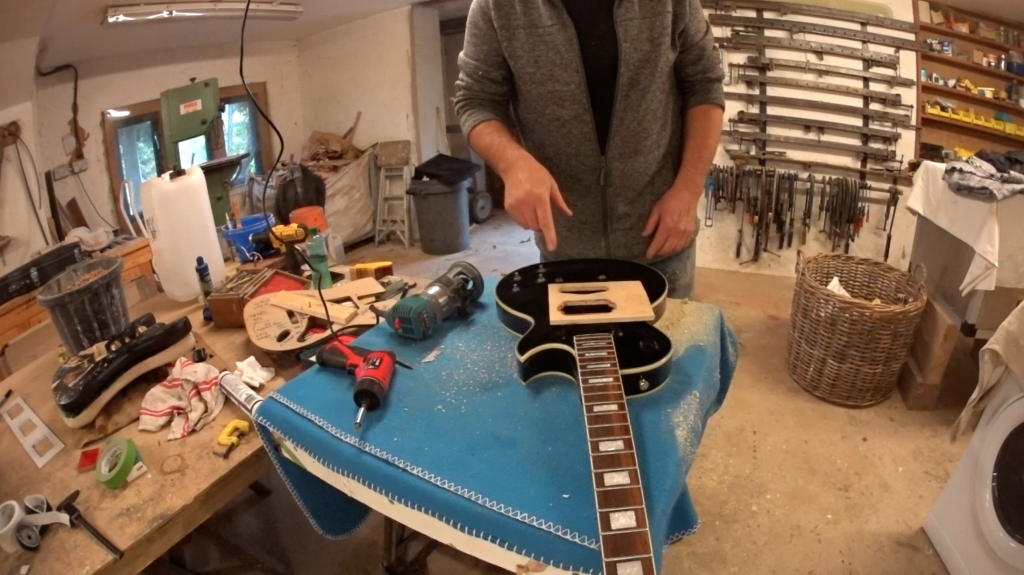

Back in the summer I bought the cheapest guitar body I could find – a sub-£30 ‘candlenut’ wood Strat shaped body direct from China. To go with it I also bought a £20 Chinese ‘strat-style’ neck. I’ve used these necks before (and up-cycled plenty of them as well) and they’re not a bad start-point. But for this fun build I didn’t want to re-fret although I did slightly re-shape the headstock slim down the back of the neck a little.

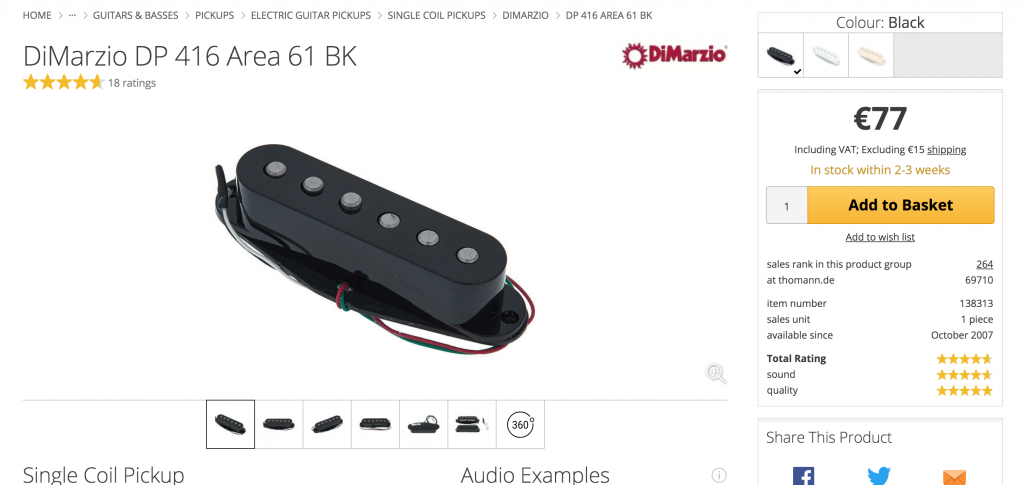

Now… as it happens, this experiment was compromised because I chose to use some decent quality components: some old Seymour Duncan ‘Livewire’ active single coil pickups and some Gotoh locking tuners, both donated by Adam Toms. I tweaked and fitted a brass adjustable nut that I’d bought from China and finished the candlenut body with the left-overs from just about every nitro spray can left over in the shed.

I’d never played with active pickups before… and this alone made it worth building the guitar. I had to velcro lead blocks between the pickups to balance out the ridiculously light body – oh, and I fitted a decent Wilkinson tremolo bridge because I happened to have a spare one. To accommodate the two 9V batteries I routed a cavity in the back of the guitar and wired everything up. I did everything in cautious stages with this build on the basis that if, at any point, it wasn’t working or worth continuing then it was going in the burner. As it happens, at each stage the guitar told me “Yes! Continue!” 🙂

Having got the geometry right and a decent action, the thing played and the pickups were GREAT fun, full of dynamics inviting me to hit them hard and gently to exploit the range of tone. I was really glad I’d gone to the trouble to try out these active pickups. So I levelled and crowned the frets but put off polishing them out until I’d played the guitar for a few weeks. And I’ve been playing it ever since. It’s currently my ‘go-to’ late night guitar to run through a loaned Fender Mustang III 100w mixed in with Spotify tunes to play along with and out through headphones.

So can you make a good guitar from cheap parts? The answer is YES with a couple of asterisks attached.

• First, you need to make sure the cheap body balances with the neck. I had to weigh it down with lead. Neck-heaviness ruins the playing experience particularly if you’re standing up with the guitar on a strap.

• Next you need to level the frets on your cheap neck to get a decent low, buzz and choke-free action – and you need to get the nut right so that it will play and stay in tune.

• Finally, and possibly most important of all you want to build this guitar around a set of pickups that sound good to your ears. If you’ve got some spare cash, put it here (and not in the body) because if this build doesn’t work out for you, you can always remove these pickups and use them somewhere else later.