I’m starting to get nervous and excited because from Nov 1 I will have the keys to a unit on a nearby industrial estate and will be getting it ready to become the new, larger Reloved Guitars base.

It’s an inevitability that you outgrow the first workshop that you start out in – whether it’s a spare room in your house, a shed, a garage or even a small lock-up space. If you stay doing what you’re doing; if you still enjoy doing it the chances are that you’re getting better at doing it. And if all 3 of the above apply, then it’s likely you’ll make enough money to call what you’re doing a business and a viable one at that. It’s highly likely that some time (quite a long time!) before you reach that point you’ll have run out room in your space and you’ll have become a ‘snug operator’. I hit that point a couple of years ago; and at that point my shed workshop felt like running a guitar business while sailing single-handedly around the world in a small yacht 🙂

Working in such a small space forces you to develop cute cute and inventive solutions to problems which in my case lent the workshop a busy, slightly ‘Heath Robinson’ feel with things hanging everywhere and tools fitted into niches and cubbyholes all over the place. The plus side of this kind of space is that you know where everything is and you’re very clear what you CAN and CAN’T do in your workshop – so you work within your limitations. Which of course brings it’s own problem otherwise known as a ‘familiar rut’ 🙂

I knew that I had outgrown the shed workshop at the point where I became aware of how much it was slowing me down and how inefficient it was making me. This really became apparent when I started making custom guitars to order because it’s at that point I started really looking at how much time and effort went into making them. The shed was good for set ups and small modifications but it was just not geared to making guitars efficiently or at a consistent level of quality. I was lucky in that I was able to sell most of the guitars I made in this highly inefficient way and that quality issues were small enough to be forgiven by customers. But the truth was that making guitars in this way simply wasn’t efficient enough or even financially profitable when time was factored in. Because I was lacking certain tools I had to achieve the same ends in different, less efficient ways. Even if I could have afforded the right tool, I didn’t have the space to fit it in. And on top of that was an over-arching limitation that many amateur guitar-makers will struggle with: the right of our residential neighbours not to have to listen to whining machinery or smell paint fumes.

So eventually the time came where I either moved and expanded the business…. or stopped doing it altogether. I took a look at everything I had achieved in developing Reloved Guitars from scratch, at the feedback and reputation that I had earned and at the friendships and customer relationships I’d gained along the way. On top of that I recognised the skills I have acquired over the years, the enjoyment and satisfaction that Reloved Guitars has given me and the fact that I’m not likely to get a ‘job’ working for anyone else in the near future in this economic climate. On top of that there was one more impetus: if I’ve achieved all that in a small shed, what else could I achieve with more space and (over time) better equipment? With all of that in mind, I decided it was time to move and expand 🙂

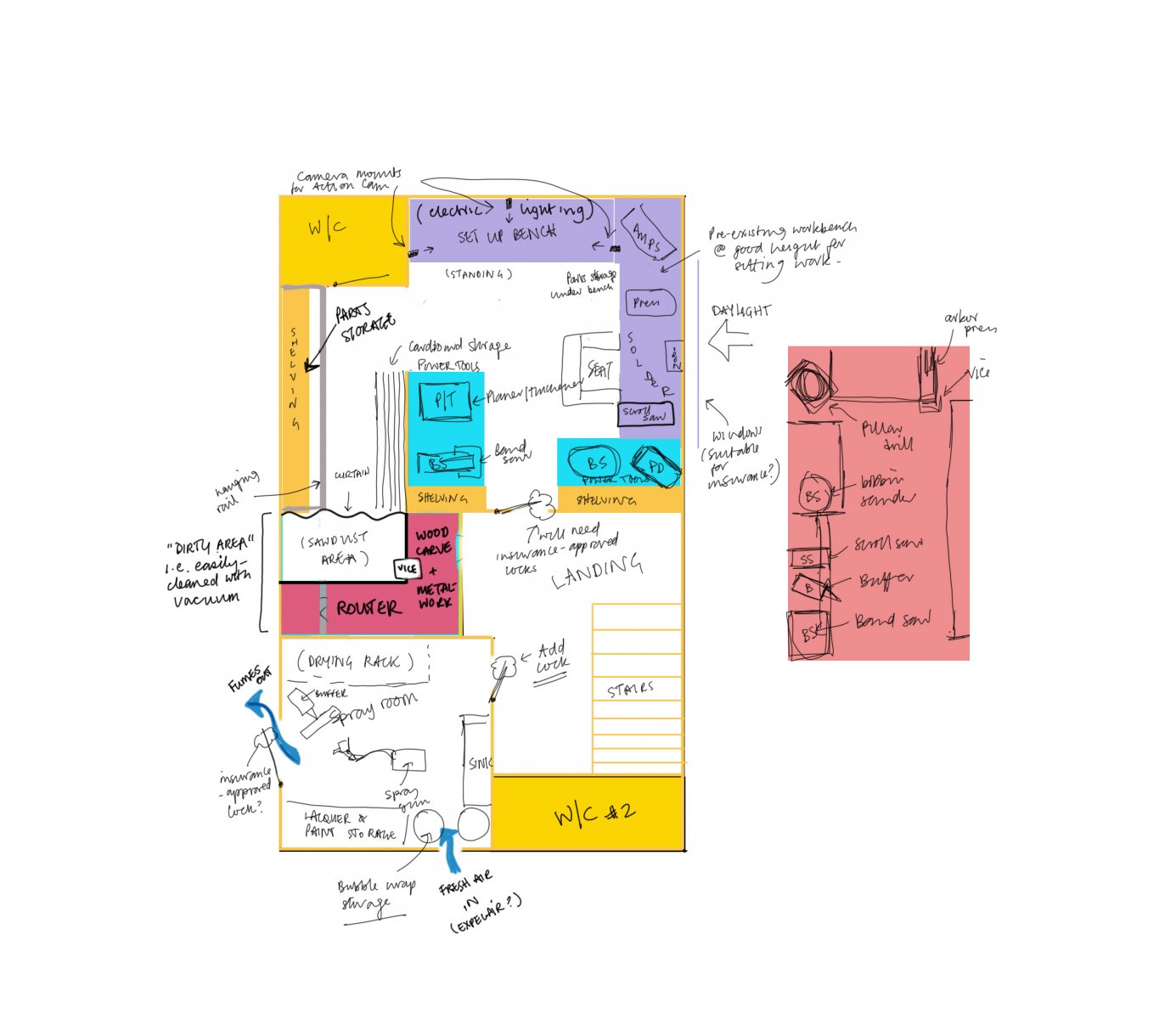

Below is my first ‘plan’ for the new space. By the front door in our home is a small – but growing – collection of unopened boxes containing ‘things for the new workshop’. Right now it consists of a woodworking vice, a box of Henry the Hoover bags (for the clean up), an Apollo Pro Spray HVLP system and a new 3M paint mask. Right there is a major ‘step-up’ for Reloved Guitars – the ability to do professional spray jobs.